5 interesting things for your week (#7)

The Straight of Messina, Salesforce Tower, a bamboo temple, Sydney Opera House sails and headed reinforcement research

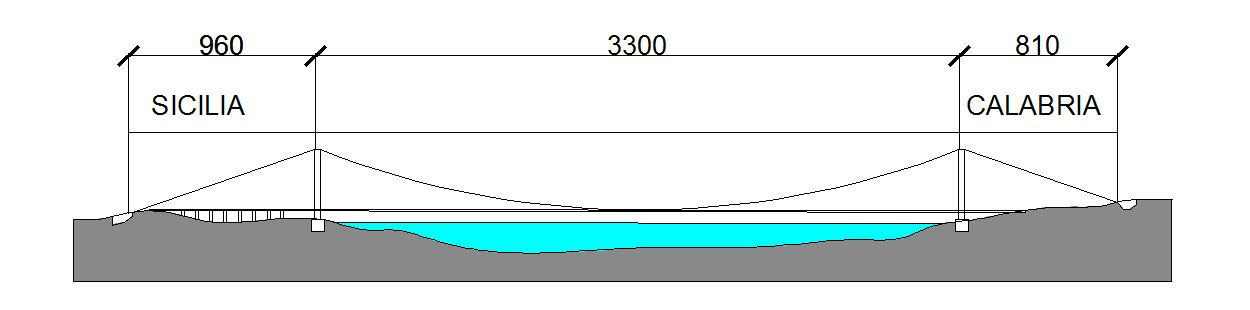

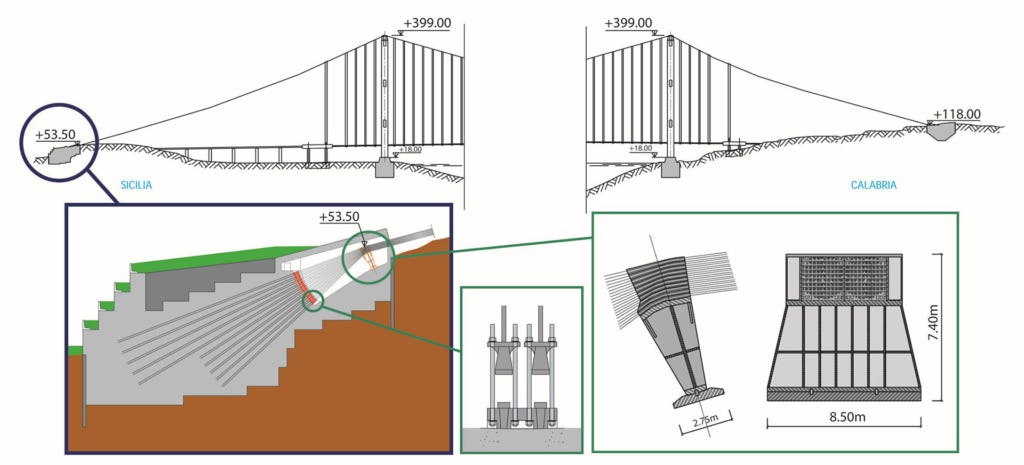

1. Straight of Messina bridge progresses

The Straight of Messina bridge is back under way. Should the project be completed, it will become the longest suspension bridge in the world at 3.3 km, smashing the previous record of 2.0 km in Turkey.

The design has been complete since the late 2000s (by COWI of course) and has only been held up due to lack of funding in the past.

From the International Database and Gallery of Structures:

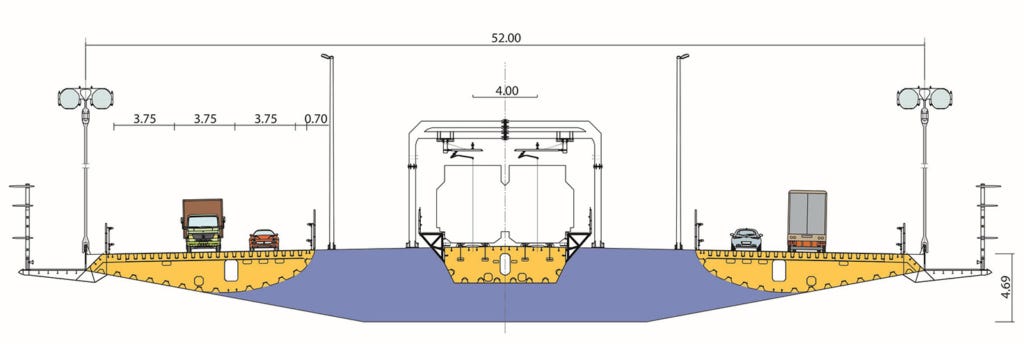

The greatest problem in designing the bridge is the aerodynamic stability of the deck under wind as well as seismic activity. A three-part box girder section was designed for the deck with the middle box carrying two railroad tracks and the outer boxes carrying the vehicular traffic. The three sections are connected by diaphragms at regular intervals corresponding to the position of the hangers. The latter connect to a pair of main cables on each side of the deck.

Like any major infrastructure project, it isn’t without controversy though. There are complaints about disruption of bird migration routes, strong currents in the strait, earthquakes and even possible infiltration of mafia groups. So we’ll see if it actually goes ahead.

2. Salesforce Tower, Chicago

This article talks to some of the challenges with building Salesforce Tower - a 58-storey building in downtown Chicago.

Salesforce Tower Chicago is a high-rise building with steel structures and a massive, four-cell vertical concrete core, which supports the tower. PERI collaborated with the project team to develop a specific sequence and schedule for delivering critical formwork components as ready-to-use systems just-in-time for use.

The contractor’s schedule and crane availability dictated the timeline for construction in addition to working backward from when certain elements needed to be complete. To aid in this schedule, PERI preassembled products into the largest shippable units to speed up on-site installation.

Since the tower crane operated through one of the cores, PERI worked to achieve additional coordination between the concrete contractor and the steel contractor during construction of the high-rise structure. The ACS Core 400 typically only has one floor, but for Salesforce Tower Chicago, an additional lower one was added so the steel contractors could attach plates to the concrete for connection to the steel beams. To achieve this, the concrete crew was hoisted up to a certain level and then walked up a 150-foot stair tower to the core for work each day.

Here’s a cool time lapse of the foundations, core and lower levels being constructed.

3. Pushing boundaries with Bamboo

I don’t think bamboo structures are coming for the mainstream any time soon, but the Luum Temple in Mexico is absolutely gorgeous.

You can tell why so many structural engineers want to get into the architectural side of things. I mean, look at this structure:

Anyway, the structure itself is five intersecting hyperbolic paraboloids (that’s a mouthful), made from bamboo arches and split bamboo beams. It’s designed for 250 km/hr winds and significant earthquake loads.

when used in split form, bamboo enables architects to craft organic, flowing shapes that defy traditional geometrical constraints, facilitating the adoption of innovative structural approaches that rely on shape stiffness and biomimicry.

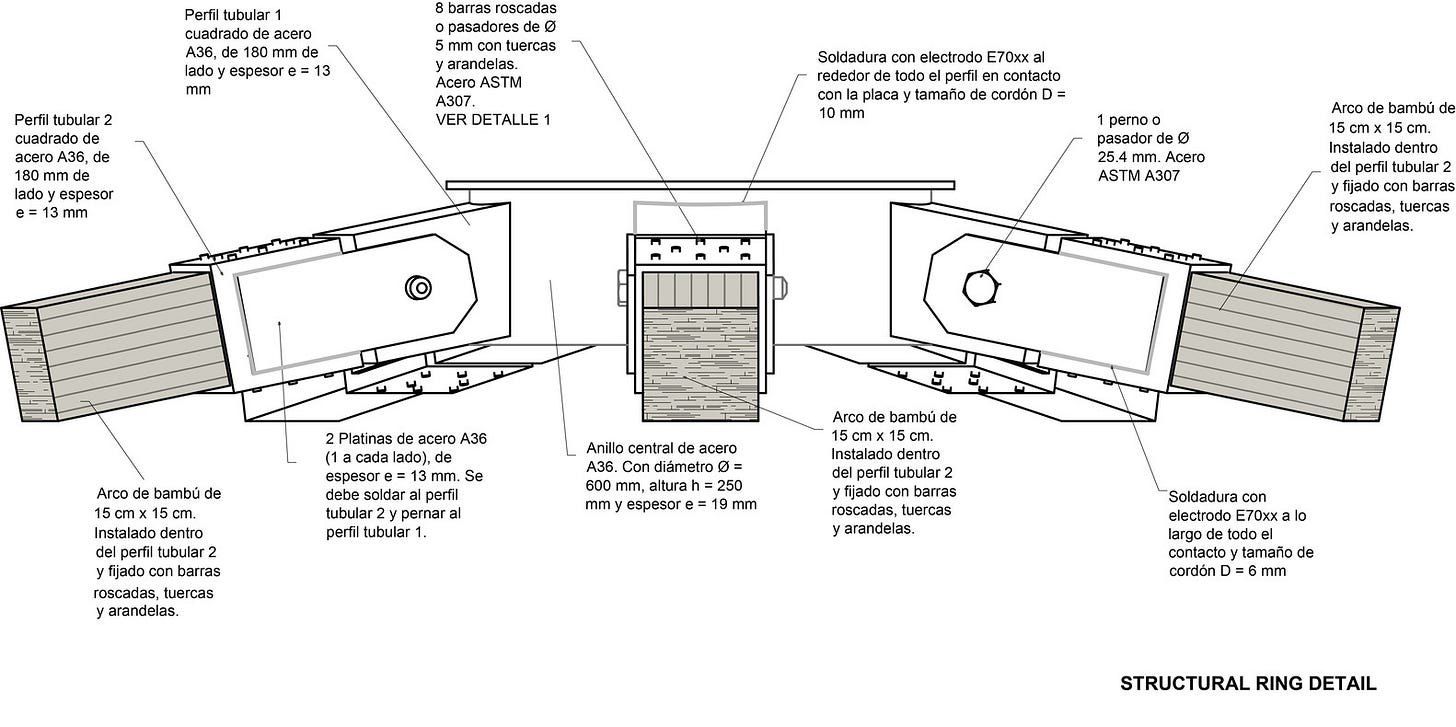

The interconnected roof diaphragm is made of cross-layers of bamboo mats —a modern nod to empirical techniques of the past that give the structure impressive resistance to lateral loads. To account for bamboo's natural flex and movement, the structure incorporates articulated foundations and a central compression ring. This approach not only captures bamboo's intrinsic strengths but also circumvents its limitations, demonstrating a model way to build sustainably and innovatively.

At the uppermost part of the structure, the primary arches converge, interconnected by a central steel compression ring. This design feature ensures each arch tip converges towards a centralized point, reminiscent of a star's radiating arms. Drawing a parallel to airplane wings, which flex and bounce to a certain extent during flight to prevent structural failure, bamboo structures adopt a similar engineering principle. To ensure the bamboo components can flex and adapt during adverse events like storms or earthquakes without fracturing, the central compression ring incorporates robust hinged connections.

4. Sydney Opera House

Not only does Robbie van Leeuwen have a bunch of fantastic Python packages, he also used to publish articles about interesting structures (and now he’s a nurse - what doesn’t this guy do?).

This particular article is about the design and construction of the Sydney Opera House roof sails.

THE iconic sails.

You know the ones.

The original design of the roof was unfeasible from a structural perspective, but Ove Arup spent six years working with the architect to arrive at a solution:

The final solution involved forming each shell with segmented post-tensioned, precast concrete ribs, all having their external surfaces described by the same sphere. By fabricating similar elements forming part of a spherical geometry, it was possible to maximise the use of repetitive elements in the construction of the shells.

Did you know that until the Sydney Opera House came along, structural engineers had not used computers for structural analysis?

All calculations were carried out manually, with the assistance of slide rules, logarithmic tables, and very rarely with calculating devices. However, even Ove Arup was humbled by the task, which required the iterative and ever evolving design of a complex, three-dimensional structure: ‘It is difficult to visualise how the necessary calculations could have been made without [computers]’.

The program that was adapted for the analysis was originally designed for structures with 18 or fewer joints. The most complex framework analysed in the design of the Opera House had 136 joints and took the computer nearly four hours to analyse the five load cases. In addition, preparation of the input data took almost three weeks. Although this seems tediously slow by modern standards, it has been estimated that the computer calculations saved almost 10 years of human work.

5. Better guidelines for using headed reinforcement?

The project explores more efficient methods of anchoring steel reinforcement in bridge structure joints with the aim of improving structural performance and accelerating construction timelines.

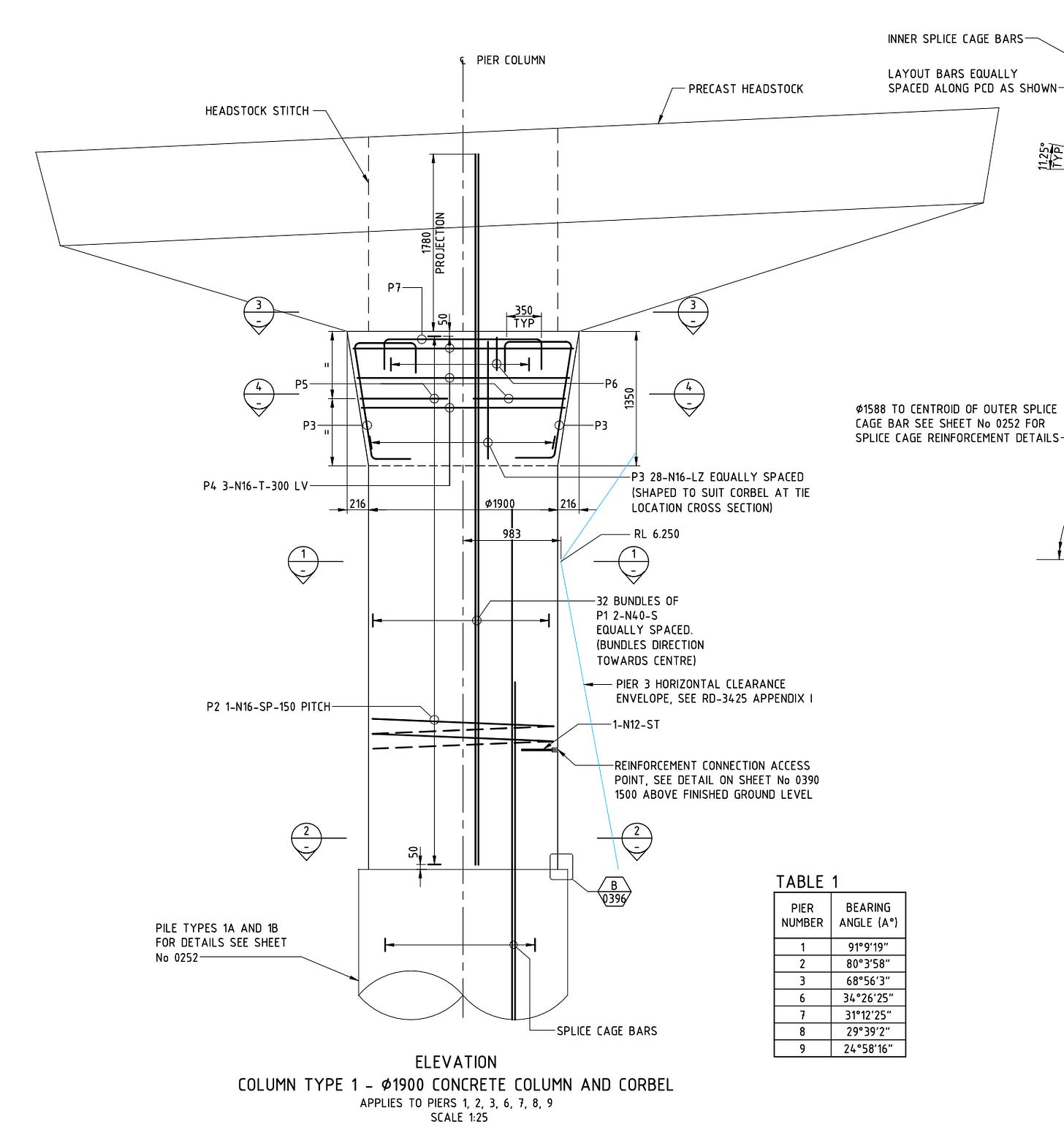

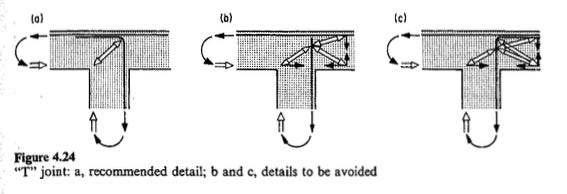

Headed and hooked bars are particularly useful in the design of bents/headstocks with the interface between the beam and column.

Standard detailing practices would have us designing the vertical reinforcement in columns with legs that extend into the beam. This allows the node for the reo carrying tension to form up as high as possible.

While this makes sense from an efficiency perspective, it’s a lot harder to build. Reinforcement congestion increases and it eliminates precast headstock options.

Researchers are studying the use of “headed bars” (or terminators) which would be attached to the end of the bar (similar to b. in the above image) and hoping to prepare some guidelines for incorporation to AASHTO to increase their adoption.

This is very similar to a detail I’ve used on a bridge in Sydney. A cast in-place column with straight bars, then a precast headstock lifted on top of the column and the void grouted.